-

Machine specification

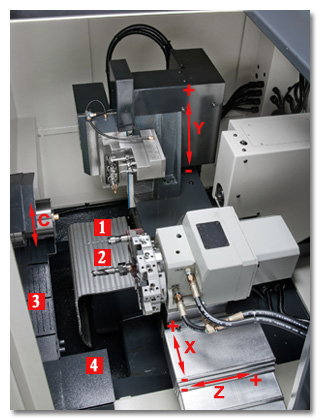

MODEL G-42HA-DET Controlled axes X, Y, Z, C Bar capacity 42mm Max. turning length Bar capacity x 2.5~3 Max. face drilling dia. Fixed drill:Ø10mm

Live drill:Ø6mmMax. face tapping size Fixed tap: M10

Live tap: M5Max. cross drilling dia. Live drill:Ø6mm Max. cross tapping size Live tap:M5 Spindle collet type 173E 3-jaw chuck size 6 inch Tool turret 8 position / servo controlled X-axis travel 140mm Z-axis travel 160mm(With tail stock) / 230mm(Without tail stock) Y-axis travel 120mm Rapid traverse 24m/min (Max.) Spindle indexing 0.001° (C axis) Spindle motor (Cont/15min.) 3.7 / 5.5KW Max. spindle speed 4500RPM Controlled axis motor Mitsubishi:X, Z axis:1KW / Y axis:0.75KW

Fanuc:0.75KWTool spindle motor (Mitsubishi) 1KW, (Fanuc) 0.75KW Hydraulic motor 0.75KW Coolant motor 0.75KW Lubricant motor 0.0035KW Face live tool Nos/collet face: 3 / ER11(Ø7mm)

Option: 2 / ER20(Ø13mm)Cross live tool Nos/collet cross: 3 / ER16(Ø10mm) OD tool shank 16 x 16 mm Fixed ID tool collet ER16(Ø10mm)

option: ER20(Ø13mm)Max. boring bar size Ø20mm Spindle bore Ø46mm Spindle center height 1120mm Required power source 3Ø220V x 10KVA Required compressed air 6 Kg/c㎡ x 50 Nl/min Machine size (WxDxH) 2,060x1,660x1,700mm

(With tail stock: 2,460x1,660x1,700mm)Machine weight 2,200 Kgs Standard Accessories

ITEM 1. Tool kit (containing tools for set-up, adjustment, and leveling bolts, block, etc) 2. Automatic lubrication system 3. Work lamp 4. 3-tiered pilot lamp 5. Coolant pump, pressure sensor 6. Hydraulic collet chuck 7. Parts catcher 8. Parts collection box 9. Bar feeder interface 10. ER16 collet nut (for cross live tools and fixed ID tools) 7 pcs 11. ER11 collet nut (for face live tools) 3 pcs 12. Cutting tools, spindle collet and drill chucks for parts to be set up, but special tools not included. Optional Accessories

ITEM 1. Magazine type auto bar feeder 2. 3-jaw chuck (6”) 3. Chip conveyor 4. Foot switch for chuck control 5. 2-position Ø20mm boring bar holder (for turret) 6. Fixed ID tool ER20 collet holder (for turret) 7. ER20 collet nut (for optional fixed ID tool ER20 collet holder or 2/ER20 face live tool attachment) 8. 18mm shank fixed OD tool holder (for interchange with cross live tool ER16 collet holder) 9. Cross live tool ER16 collet holder (spare for use when face live tool attachment is to be removed and interchange) 10. Safety door switch for cutting tool room 11. Tail stock 12. Live center for the tail stock 13. Transformer (3Ø380~415 / 220V x 10KVA) 14. 2/ER20 type face live tool attachment * All specification are subject to change without prior notice.

* The machine can be equipped with either a Fanuc or Mitsubishi controller upon request.

-

- ID, OD, cross machining, off-center drilling and tapping can be efficiently accomplished in one setup.

- The Cs-axis provides contouring functions (words and pattern engraving). The spindle accurately orientates at any angle.

- 8-position servo turret.

- Pneumatically operated tailstock helps to hold long workpiece firmly.

- If 4 cross live tools are required, the face live tool attachmentcan be removed and interchanged with a spare cross live tool ER16 collet holder (option item No.9).

- The cross live tool ER16 collet holder is cartridge type, and can be interchanged with 18mm shank fixed OD tool holder.

- The C-axis is equipped with a disc brake, ensuring improved stability of machining.

- Once parts machining is finished, the parts catcher will deliver the parts to the parts collection box, and then can be taken out outside the machine.

- Swing control box facilitates running test.

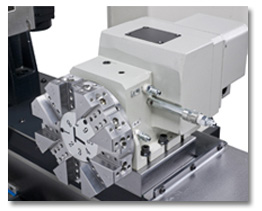

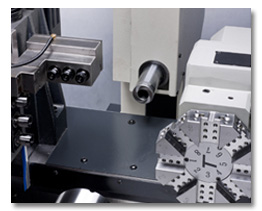

8-position Servo Turret

- The servo turret can be fitted with ID and OD tools.

- Also available to fit with a 2-position ID tool holder (optional).

Pneumatically Operated Tailstock

- The stroke of air cylinder that actuates the tailstock quill is controlled by proximity switch to suit workpiece length.

- The air cylinder features buffering function to eliminate vibration of the tailstock while machining.

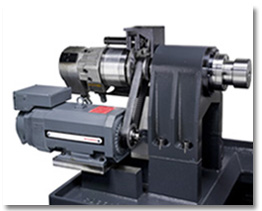

C-axis Brake

- The C-axis employs a hydraulic disc brake, enabling spindle orientating accuracy to reach 0.001. Another benefit is to lock the spindle securely for increasing stability when performing heavy cutting on end and side faces. (Such as cross drilling, tapping, milling and end-face off-center machining.)

- Fixed ID tool ER16 collet holder

- Fixed ID tool ER20 collet holder

- Parts catcher

- Parts box

Box door opens automatically when parts catcher moves to receive the completed parts.

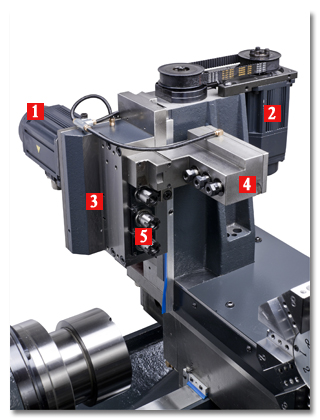

- Live tool spindle motor

- Y-axis motor

- Cross live tool attachment (ER16)

- Detachable face live tool attachment (ER11)

- Cross live tool ER16 collet holder

It can be interchanged with #8 optional 18mm shank fixed OD tool holder.

Fixed ID tool ER16 collet holder (standard, 4 pcs)

ER16 collet nut (standard, 7 pcs)

18mm shank fixed OD tool holder (optional)

Fixed ID tool ER20 collet holder with nut (optional)

-

-