-

Description

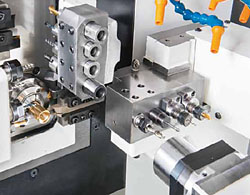

More functions, shorter cycle time, more affordable, high precision, high rigidity.

Machine specification

MODEL GO-126 GO-206-II Machining capacity Max. material bar diameter at main psindle 12mm 20 mm Max. work chucking diameter ar back spindle 12mm 20 mm Max. machining length 170 mm (Direct-drive guide bushing)

80 mm (Mechanical-drive guide bushing)

210 mm (Fixed guide bushing)

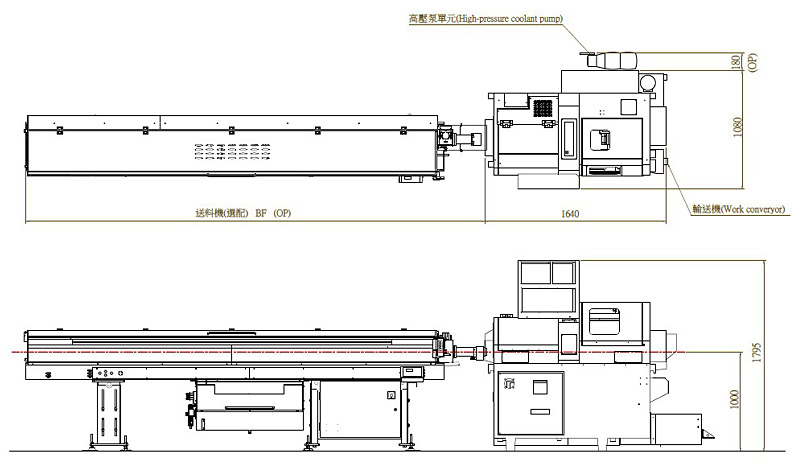

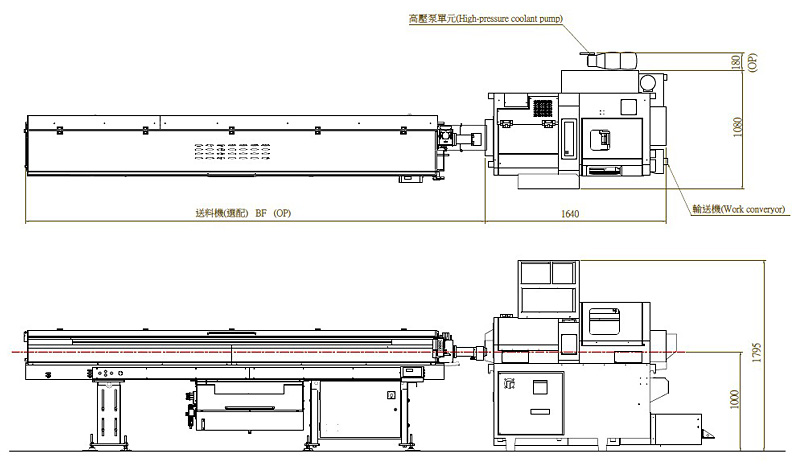

30mm(GO-126) / 45 mm (GO-206-II) (Guide bushing-less)Max. main spindle drilling / tapping diameter Ø8mm / M6 Ø10 mm / M8 Max. sub spindle drilling / tapping diameter Ø8 mm / M6 Max. drilling / tapping dia. of cross tool spindle Ø6 mm / M5 Max. mountable slitting saw dia. / Nos. at cross tool post Ø30 mm x 2 Max. drilling / tapping diameter of back tool spindle Ø8 mm / M6 Max. drilling / tapping diameter of back cross tool spindle Ø6 mm / M5 Machine capacity Max. speed ain spindle 120,000 rpm (※1) 10,000 rpm (※1) Back spindle 120,000 rpm (※1) 10,000 rpm (※2) Rotary guide bushing otor direct-drive 120,000 rpm (※1) 10,000 rpm Mechanical-drive 8,000 rpm Cross tool spindle 5,000 rpm Back tool spindle 5,000 rpm Tool size OD turn tool shank 12 x 12 x 85 mm Boring tool shank (for face/back & back tool post) Ø20 mm Chuck for cross live tools ER11 x 2 / ER16 x 2 Chuck for back live tools ER16 x 4 Rapid traverse 30 m/min (X: 24 m/min) Controlled axes 6 (X1, Y1, Z1, X2, Y2, Z2) Motors Main spindle motor 1.5 / 2.2 KW (Rated/15min) 2.2 / 3.7 KW (Rated/15min) Back spindle motor 1.5 / 2.2 KW (Rated/15min) Rotary guide bushing 0.75 / 1.1 KW (Rated/15min) Axis motor 0.5 KW Y2 axis motor 0.5 KW Cross tool spindle motor 0.5 KW Back tool spindle motor 0.5 KW Coolant pump motor 0.75 KW Lubrication pump motor 0.011 KW Spindle cooling oil pump motor 0.19 KW Axis trave X1 84 mm Y1 160 mm Z1 (fixed guide bushing) 250 mm X2 335 mm Z2 170 mm Y2 60 mm Others Net weight 1,700 Kgs Equipment capacity 11 KVA Power source required ≧9 KVA Air pressure ≧0.4 MPa (4KG/cm2) Air flow ≧30 NL/min Cutting coolant tank capacity 115L Machine size LxWxH 1,640 x 1,080 x 1,700 cm - Normal / limited main spindle speed is 6,000 / 8,000RPM when mechanical-drive rotary guide bushing is used.

- Speed should be limited to 10,000RPM when front work discharge unit is mounted.

- Alll specification are subject to change without notice in advance.

Standard NC specification

MODEL GO-126 / GO-206-II Contrlooer Fanuc 0i-TF No. of controlled axes 6 (X1,Y1,Z1,X2,Y2,Z2) Spindles synchronized (speed & phase angle) S1- S2 ( Main spindle -Back spindle) Axes synchronized Z1-Z2 Axes composite control Z1-Z2 Axes simultaneously controlled Max. 4 axes / each path Least input increment 0.001mm ( Diametrical designation for X axes) Max. programmable dimension ± 8 digits Rapid traverse rate 30m / min (X1: 24 m / min) Spindle / Feed rate override 0~150% / 10% increments Absolute / incremental command X,Z,Y: Absolute / U,W,V: Incremental Tool offset pairs ±6 digits / 64 pairs Display unit 10.4”color LCD Programs stored 1 megabytes / 400 pcs (path) Standard NC function

MODEL GO-126 / GO-206-II Main spindle C axis standard Sub spindle C axis standard Coress tool spindle rigid tapping standard Threading, synchronous cutting standard Continuous thread cutting standard Manual handle feed standard Memory card I/O interface standard USB interface standard Background editing standard Run time and parts count display standard Custom marco standard Spindle synchronous control standard Axis synchronous control standard Tool geometry / wear offset standard Programmable data input standard R Chamfering / corner R standard Tool nose radius compensation standard Multiple repetitive cycle standard Extended part program editing standard Inch / metric conversion standard Canned cycles for drilling standard Rigid tapping (Main / back spindle) standard Manual handle retrace standard Polygon turning standard Standard accessories&software

Item Tool life management Main spindle collet sleeve (for round bar machining) Back spindle collet sleeve (for round bar machining) Safety door Coolant flow switch Spindle cooling unit Standard tools Slide fixing blocks (for transit) Automatic power shut-off Face / back ID tool post 4-spindle cross tool attachment Back tool post (with 4 fixed tools, 4 live tools) (GO-126 / GO-206-II) Cutting coolant nozzles 3-tiered warning lamp set Work light Coolant pump Work catcher Bar feeder interface Fixed guide bushing Guide bushing-less kit Spindle brake (available only for machine with C1 axis) Back spindle brake (available only for machine with C2 axis) Front work discharge (from back spindle) Rear work discharge (from back spindle) Optional accessories

Item Motor direct-drive rotary guide bushing Mechanical-drive rotary guide bushing Oil cooler Oil mist collector High pressure coolant system Work conveyor Chip conveyor and chips cart Main spindle collet sleeve for non-rounded bar Sub spindle collet sleeve for non-rounded bar Small- bore spindle sleeve for reducing bar vibration ER11 drill collet holder (Ø20- shank , for face/ back , or back ID tool post) ER16 drill collet holder (Ø20- shank , for face/ back or back ID tool post) Double-headed ER11 drill collet holder (Ø20- shank , for face/back ID tool post) Double-headed ER11/ER16 drill collet holder (Ø20- shank, for face/back ID tool post) Bar feeder Tooling zone work light -

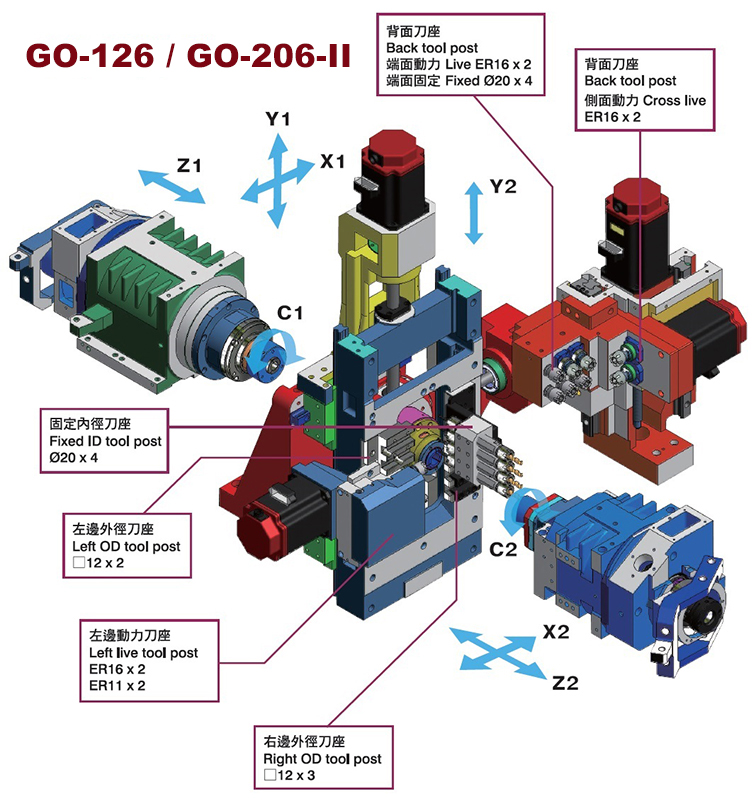

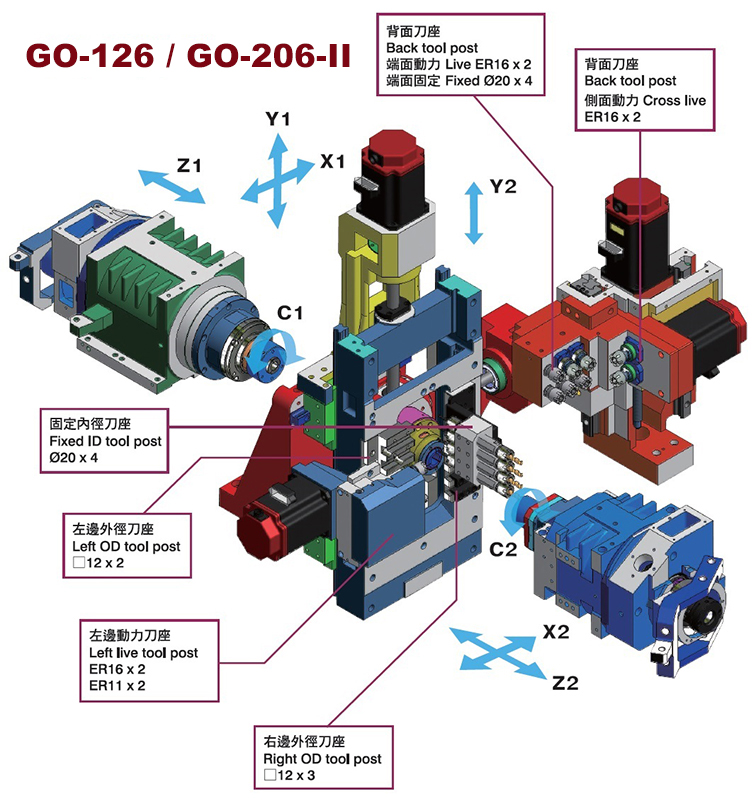

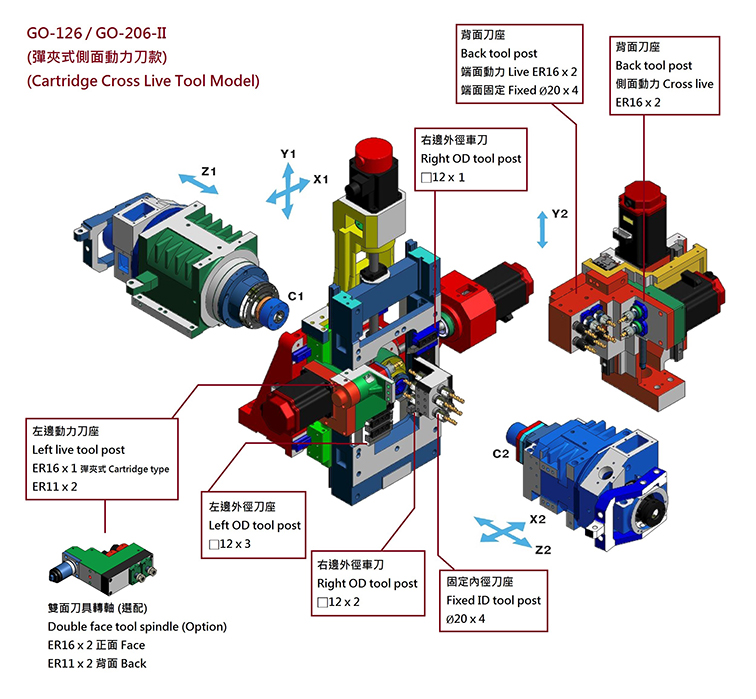

- Exactly simultaneous tooling at main spindle side and back spindle side

- With separate back tool post, and back spindle cross traveling (X2, Z2) , tooling at back spindle side(S2) can be performed at the same time while tooling at main spindle side is under way, without need to wait with each other, reducing cycle time greatly.

- 21-tool capacity

- Five tools for OD, four tools for cross drilling milling, four tools for face ID working, ten tools for back ID and two live tools back cross milling working make it possible for completed a wide variety of tooling jobs at one-time.

- Built-in main and back spindle motors increasing tooling accuracy.

- Increased accuracy of speed and phase angle while both spindle synchronize.

- With synchronization function of Z1 and Z2 axes, possible to do R cut-off, etc.

- Direct motor-drive rotary guide bushing, available for high-speed and accurate machining.

- Max. speed : 10,000 min-1 Max. machining length : 170 mm Geometry accuracy, dimension accuracy and surface roughness are much improved, with less noise even at high speed.

- “ Not suitable for water-soluble cutting coolant.

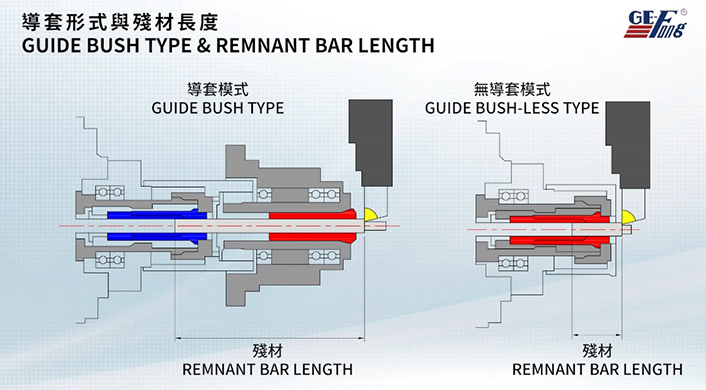

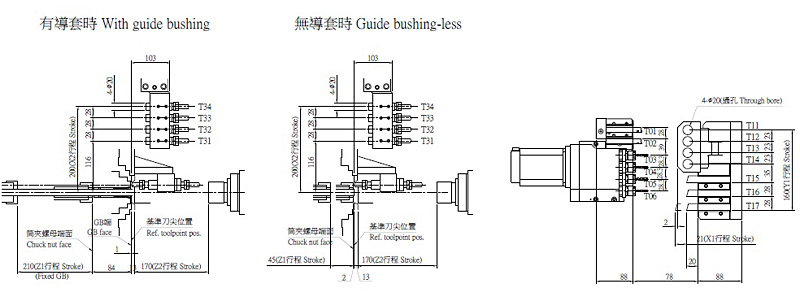

- Guide bushing type or guide bushing-less type is selectable according to length of the parts to be produced.

- Guide bushing-less type does not require ground bar stocks, suitable for cold drawn bar machining also, reducing the remaining bar length.

- 4-spindle cross tool attachment can be mounted, available for Y-axis complex tooling, such as cross drilling, tapping, up-down milling, etc.

- Single or double-headed drill collet holder can be mounted at №20- through bore ID tool post, available for face, back ID working.

- High rigid cast machine bed, absorbing the vibration caused by high speed rotation and rapid traverse.

- Higher precision

- Rigidity of both the tool posts at main spindle side and the feed axis slide guide are upped, so tooling accuracy is not influenced by cutting load variation.

- Based on thermal physics, main / back headstocks, and X axes (X1, X2) are all installed horizontally, reducing the heat-induced deformation to minimum.

- Reduced tooling idle time

- Rapid traverse : Max. 32 m / min (X: 24 m / min)

- Tool span is only 28 mm, greatly reducing tool change time.

- Maximum high- speed control, reducing idle time.

- Double control system, programs can be specified at main and back spindle side separately, and they are read and processed at the same time.

- With X2 axis and independent back tool post, simultaneous tooling at main and back spindle side can be done.

- High-speed cycle tooling

- M and T codes, axis feed can be specified at the same single block.

- Direct C-axis indexing.

- If with C-axis (option), when spindle indexing is done, it stops at indexed position directly, without need to return to reference point, reducing spindle indexing time.

- MHigh-speed thread cutting function, reducing thread cutting time.

- Large chips pan, good for long-time unattended operation. Also, possible for taking out the products and removing the chips during machine operation.

- Friendly, easy operation

- Operation panel is closer to cutting zone, which also can be rotated, convenient for seeing the program on monitor and tool movement, etc.

- Lift-to-full open safety door for cutting zone room, convenient for tool setup.

- Easy-to-rake out chips discharge port design.

- Chips pan is put on coolant circulation inlet, convenient for cleaning.

- GE FONG-made software is provided as standard accessory for easier operation such as automatic programming, tool-tip height compensation, tool life management, periodic maintenance screen, and automatic cut-off, automatic facing, tool interference check, options (as work conveyor, etc.) ON/OFF setting, etc.

- Mirror image function is convenient for programming for machines with opposed tool slides as GO-205-II. Also,¨mirror image ON〃(G68) is built in the GE FONG-made opposed tool calling software, so without need to specify G68 or G69 with the tool called, preventing tool crash due to programming miss.

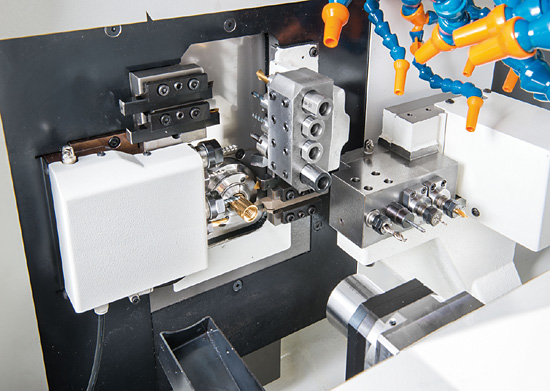

Tooling zone

Standard machine tool post layout

Optional machine tool post layout

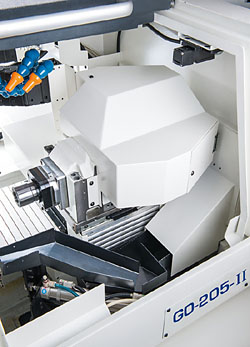

External view

- Exactly simultaneous tooling at main spindle side and back spindle side

-

-